Herramienta Inteligente de Optimización de la Operación y el Mantenimiento de Plantas Fotovoltaicas, basada en nuevos sistemas de monitorización embarcados en UAVs

GRANT AGREEMENT ID: RTC-2016-5694-3

GRANTED: € 648.510

FUNDED:

![]()

1-Oct-2016-31-Dec-2019

Backgound

The main objective of the SCARAB project is to develop a support system for the operation and maintenance of photovoltaic plants composed of the following sub-systems:

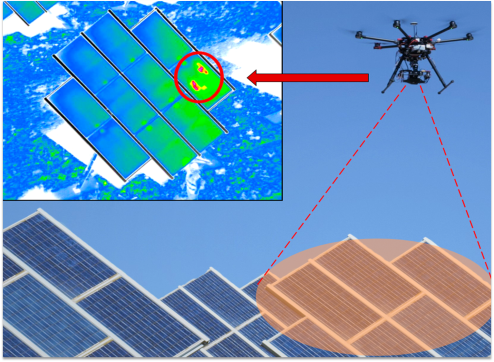

Unmanned aerial vehicle (UAV or drone) adapted to accommodate different sensors and follow different trajectories according to the technology and type of installation of the photovoltaic panel;

- Algorithms that allow to detect and classify the possible causes of reduction of the performance of the panels such as breakage, dirt or degradation;

- Algorithms that, based on on-board sensors and other plant information, will provide reliable and robust indicators of the technical and economic performance of the system;

- Application optimization of maintenance activities.

With all this, it will help to respond to the main challenge facing photovoltaic solar plants: achieve a high profitability that allows them to compete with other sources of energy, both fossil and renewable. The improvements that the project will bring at the operational level include the elimination of lifting means for the inspection of panels, reducing the time taken for measurements and post-processing, and facilitating decision-making in order to carry out the operation and maintenance activities with the minimum costs and maximizing the life time of the plant.

At a technical level, the SCARAB project addresses the development of new technologies in two branches:

1.Monitoring and signal processing for the inspection and automatic detection of faults in photovoltaic panels through the use of more efficient sensors

2.Information technologies, developing advanced fault classification algorithms, estimating the status of the solar plant and optimizing maintenance strategies.

In relation to the first line of action, they are beginning to use unmanned vehicles for the inspection of photovoltaic plants using thermographic or visible-spectrum cameras, which allows reducing the time taken for measurements. However, the expensive post-processing of the information captured to detect faults is done in a traditional way, reviewing the images one by one. For this reason, the present project raises the automation of the analysis to complement the reduction of time and costs achieved with aerial inspection with the additional optimization that is achieved with the automatic diagnosis from the collected data.

In relation to the second technological line, it is intended to go beyond the current state of the art by developing intelligent algorithms that use the failure indicators detected with the previous sub-system and the correlations with the most relevant exogenous information (power produced, climatology, costs of energy and labor, repair times, etc.). As a result, the plant operator will have a decision support tool to determine the optimal maintenance strategy.

In the present report a Work Plan has been proposed with a duration of 36 months, which covers the technical objectives described, and which is structured in 8 work packages.

In short, the SCARAB project is aligned with the needs of society (Challenges) and with the national technological development agendas (National Renewable Energy Plan 2011-2020) and European (H2020) as explained in the chapter on «Internationalization» of this proposal. The execution of the project would not only allow the development of necessary solutions for society and competitiveness, but would strengthen the international leadership capacity in emerging markets and in future R & D & I projects.

Objectives

The general objective of the SCARAB project is to increase the efficiency and effectiveness of operation and maintenance activities in photovoltaic solar plants. To this end, new technologies for automation of inspections, diagnosis and intelligent analysis of information will be developed, which will support the company providing maintenance services and significantly improve its competitiveness.

After reviewing current practices, it has been decided to focus on technological development to solve four O & M processes that are currently susceptible to improvement and would have a great impact on time and costs:

1. Eliminate the use of lifting equipment (cranes) and the need for work at height that involves a high cost and a risk.

2. Accelerate the thermal measurements of panel diagnostics

3. Allow more frequent inspections.

4. Facilitate the analysis of the collected data to detect faults in PV panels and determine their severity.

5. Facilitate the analysis of the global state of the system and its economic performance.

6. Plantear optimal O & M strategies that contribute to lengthen the life time of the plant.

The project will achieve important strategic objectives for Ingenium and Ingeteam Service by developing and incorporating new knowledge and offering the market advanced services that position it in advantage over its competitors. The results that are expected to be obtained are not only aimed at the photovoltaic sector, but will be extrapolated to other sectors such as wind or industrial. In order to achieve the general objectives, there are a series of preliminary stages and scientific-technical objectives that must be addressed and that at the same time allow to evaluate the progress of the project.

These are described below:

O1 Integrate sensors on board drone.

This objective groups all the activities necessary to automate the tasks prior to the inspection of the panels: 1) move from one panel to the next sequentially and 2) positioning the sensor with the appropriate angle with respect to the point to be measured. For each tracking technology: fixed, 1-axis and 2-axis, there are specific requirements and limitations. In many cases lifting means are required to take the measurement at the moment when the panel is facing upwards, beyond the reach of the technician. Otherwise, the measure would not be made under the right conditions to detect failures. For this reason, it is necessary to consider the casuistry of photovoltaic plants and develop an electromechanical system (power supply, mechanical fixation, delimitation and orientation) to mount the sensors on an air vehicle that has sufficient range, autonomy and power for it.

O2 Automate the taking of measures indicative of the state of health of the PV panels.

The detection of faults and loss of performance in photovoltaic panels can be due to multiple causes and manifested in several ways. This technological objective is oriented to: 1) characterize the faults in PV panels; 2) specify, select and adapt the data acquisition module, the UAV and different commercially available sensors to detect problems in different photovoltaic technologies; 3) specify and develop an automatic and configurable aerial inspection system with parameters such as the route, the sampling frequency, the height and inclination of the panels, etc.

O3 Automate the PV panel diagnostics.

After the flight mission of the UAV, sensor data is received, predictably in a ground equipment. To avoid the need for expensive analysis by a thermography expert or the detection technique used, the next objective is to automate the interpretation of the data. To do this, algorithms must be developed that extract fault indicators, determine if they are outside the optimum operating range and classify the deviation. In this way, considerable savings are expected in terms of time and costs, which can be decisive both in small distributed plants and in plants of several hundred MW.

O4 Generate robust performance and degradation indicators both at the panel level and at the plant level.

In addition to the specific faults that may be encountered during the inspection of the panels, it is important to detect progressive losses of performance that are generally produced by the degradation of the cells or by the accumulated dirt on their surface. This objective could not be achieved without taking into account the environmental conditions in which the measures are carried out and without having historical data. Therefore, variables of the plant SCADA and other relevant information must be acquired (energy price, weather forecasts, etc.), develop variable correlation algorithms and develop comparison and trend detection algorithms with historical data.

O5 Generate software tools for optimal operation and maintenance of PV plants.

Having reliable information about the state of health of the photovoltaic panels and the plant as a whole is useless if that information is not assimilated and used to make decisions that improve the situation through operation and maintenance. The objective is, therefore, to provide the information to the operator in such a way that he can make better decisions. Said tool should consider not only technical but also economic parameters, and provide a quantitative estimate of the impact that a certain action would have on the performance of the system.